Operating model

This is how our machining service works

Below we describe how our machining service proceeds in practice, implementing our certified operation. At the core of everyday life is personal service, dialogue, skilled people and modern equipment. Quality and cost-effectiveness are not mutually exclusive, but are a common cause and advantage.

1. Customer need

Contact is enough. You just tell us your needs, whether it’s a prototype stage, a pre-designed new product to be machined, or an additional series of an already made product.

Regardless of which stage of the product’s life cycle it is, in follow-up discussions you will get our expert opinion on the necessary measures and the most cost-effective way to manufacture your product.

2. Viewing the plan

Before production starts, the plan is reviewed. We go through the quality criteria and other things that need to be taken into account.

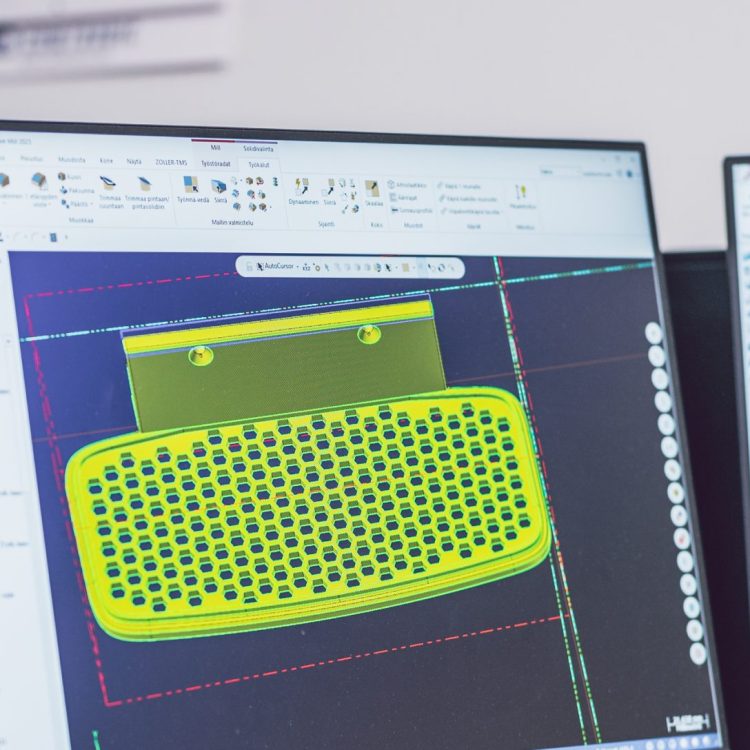

3. Proto-stages and production

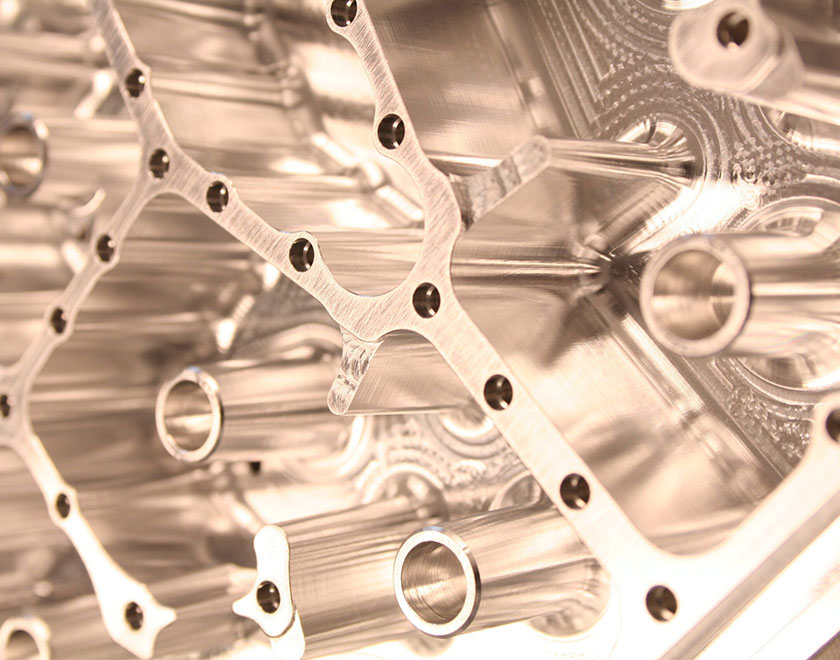

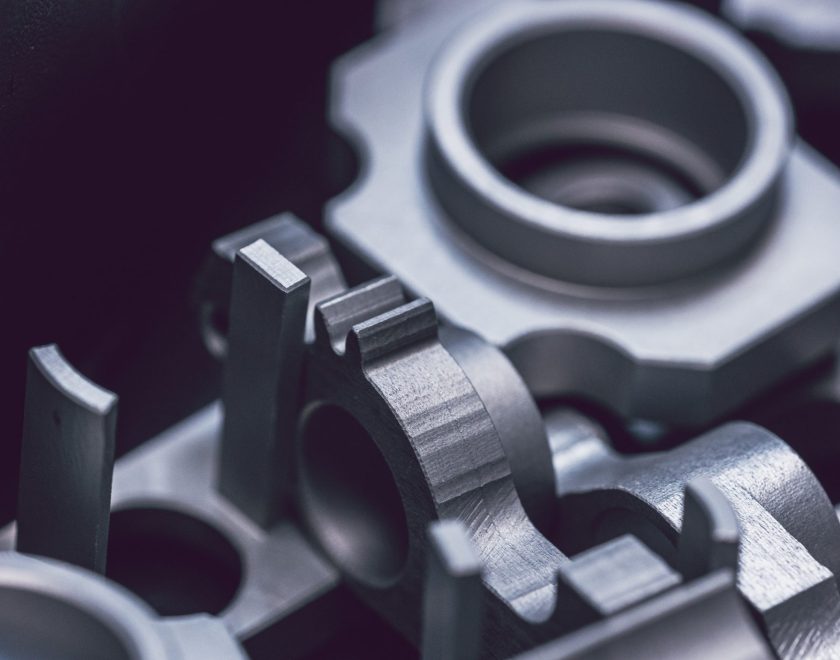

The protophase includes examining the details of the part and defining machining from a production point of view. Based on the design drawings, we think about the most efficient manufacturing method: whether to use lathes or milling, or both. If necessary, we take a stand on material choices, propose changes to speed up production and optimize material flow.

In production, the size of the manufacturing batch and the expected life cycle of the product affect the choices.

4. Findings and final product

In the name of common interest, even after the first manufacturing batches, production is optimized. We observed whether, for example, we can further reduce material waste or shorten the working time. The purpose is always to produce machining services as cost-effectively as possible. Over the course of more than 20 years, the data bank has accumulated rapidly, but we still treat each order as its own new individual work.

5. Production, storage and delivery

Depending on the product, quantities and life cycle, we have divided our production activities into four different categories:

- prototype pieces and small batches

- serial production (= production takes one shift and is repetitive)

- lathe products

- configuration

Our services also include forecasting deliveries. According to the agreement, we order manufacturing material into the warehouse to speed up deliveries, store the final product and deliver the agreed batch of products with the shortest possible delivery time.

We deliver individual orders to the agreed place on the agreed schedule.

we store the final product and deliver the agreed batch of products in the shortest possible delivery time.

6. Termination of life cycle

If the product’s life cycle is coming to an end, we agree well in advance that no manufacturing materials or even finished products remain in the warehouse. In this respect too, we emphasize dialogue and common interest in our service.